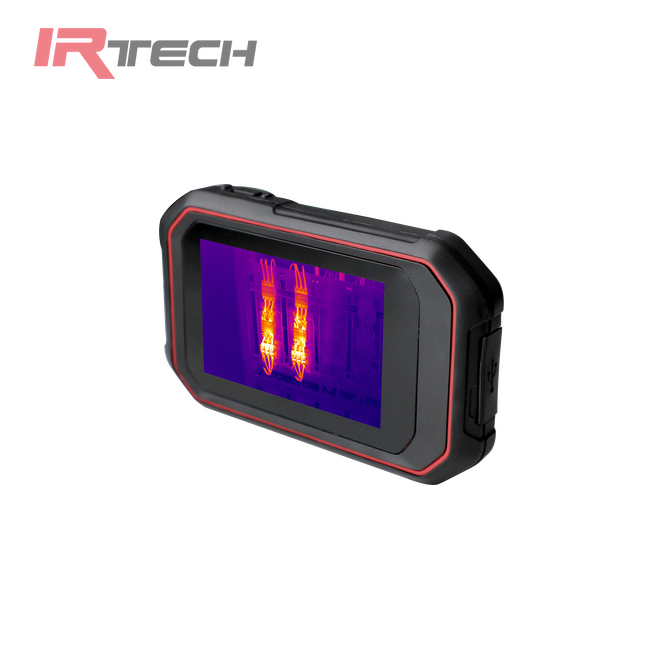

DLSC-N Series Thermal Imaging System

Front-end measurement,high accuracy

H.264 network digital video storage and transmission

Auto focus

rich interfaces, easy integration

only power supply and network cable needed to plug into the system, simple and convenient

|

Item |

DLSC- N318 |

DLSC- N337 |

DLSC- N625 |

DLSC- N642 |

|

|

Detector |

Type |

Uncooled FPA |

|||

|

Resolution |

384×288 |

640×480 |

|||

|

Imaging Performance |

FOV/Min Focal Length |

25°×19°/ 0.3m |

12°×9°/ 0.5m |

25°×19°/ 0.3m |

15°×11°/ 1m |

|

Spatial Resolution |

1.39 mrad |

0.67 mrad |

0.68 mrad |

0.41 mrad |

|

|

NETD |

≤0.06℃@30℃ |

||||

|

Frame Rate |

50/60Hz |

||||

|

Focus |

Manual / Automatic |

||||

|

Spectral Range |

8~14μm |

||||

|

Visible camera |

Zoom |

20X / 30X Optical Zoom |

|||

|

Resolution |

2 Million Pixels, 1080P |

||||

|

Min Illumination |

0.005(Lux) |

||||

|

PTZ |

Horizontal rotation angle |

0°~360° Continuous rotation |

|||

|

Preset Position |

MAX 255, Angle Feedback Support |

||||

|

Mounting & Pitching Angle |

Top Mounting, -90°~+90° |

||||

|

Measurement |

Range |

-20℃~+650℃ |

|||

|

Accuracy |

±2℃ or ±2% of reading (whichever is greater) |

||||

|

Correction |

Manual / Automatic |

||||

|

Mode |

Free Setting in Software |

||||

|

Storage |

Raw Image |

Raw images real-time transfer via client control software, the images are analyzable and measureable |

|||

|

Storage Format |

H.264 real-time recording |

||||

|

Single Frame Image capture in BMP format |

|||||

|

Power |

External Power |

220AC |

|||

|

Power Consumption |

≤75W(25℃ nominal) |

||||

|

Environment |

Operating Temp |

-40℃~+65℃ |

|||

|

Protection Class |

IP66 |

||||

|

Humidity |

≤90% (Non-condensing) |

||||

|

Automatic identification management |

Automatically identify the heat map acquired by the system, and identify valid target of the heat map through image registration to ensure the efficiency of temperature detection. |

||||

|

Anti-false alarm identification System |

All temperature measurements are based on valid target recognition. According to the inspection strategy, measure only marked devices, and automatically eliminate disruptive heat source, effectively preventing false alarms. |

||||

|

Detailed equipment work status management |

Establish a management system for all equipment and components, during automatic cruising, perform temperature analysis and record of all equipment components within the scope of inspection of the infrared camera, specific to detailed equipment failure location. |

||||

|

Automatic cruise |

Preset PTZs can be used to set up more than 128 regular check positions, provide multiple modes of auto-cruise programs, realizing fully automatic operation, equipment working status inspection several times a day, automatic warnings, automatic report output. Reduce the number of on-site visits, and improving the efficiency of operators. |

||||

|

Automatic warning |

During system cruising, it will automatically alarm if abnormal temperature are found on the target device, the alarm information includes text messages and sound messages, informing the operator for specific information of the alarm location, in order to track the fault point, confirm the alarm condition and eliminate the fault. |

||||

|

Automatically generate reports |

System software can automatically generate device temperature analysis report for a single frame of infrared image, or comprehensive report. The system can automatically record the temperature value of each temperature measurement, and generate a temperature report to reflect the temp changes of the contact point in a certain period of time. |

||||

|

Infrared panorama |

Provides wide field of view, high accuracy, 360 degree full view infrared image |

||||

|

Front-end temperature measurement method |

Front-end temperature measurement, directly output the temperature data without computer processing, and the temperature signal is directly superimposed on the video signal |

||||

|

Dual-field surveillance, assisted identification |

The infrared camera and the high-magnification visible light camera are mounted on the same head, not only ensure that the two cameras monitor the same position, but also solve the problem that the infrared thermal image is difficult to identify device installation position, convenient for instantly checking of the hot spots of equipment |

||||

|

Low network bandwidth |

Supports low-bandwidth operation mode, occupy bandwidth less than 0.8M under the condition of guaranteeing transmission of temperature data and image data at the same time. |

||||

|

Development kit |

Instrument real-time control development kit |

||||

|

Image Processing Development Kit |

|||||

|

Infrared image transformation equipment intelligent identification development kit |

|||||

|

Client Remote Control Development Kit |

|||||

|

Client Web Remote Control Development Kit |

|||||

|

Development Support Response |

Instant response, 24-hour on-site support, full Chinese support |

||||

|

Universal protocol support |

Direct support for IEC60870-5-104 protocol Direct support for IEC61850 protocol |

||||